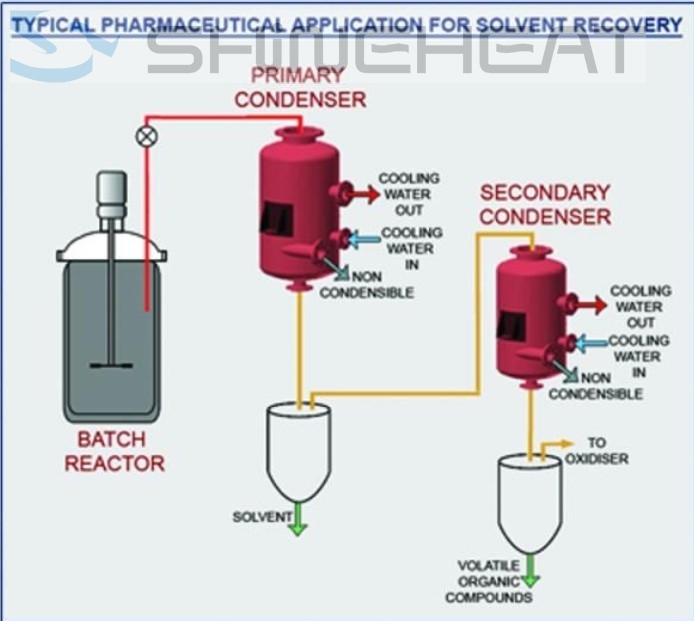

Spiral Heat Exchanger apply for Solvent Condenser in Bulk Drug Industries.

The Job Description

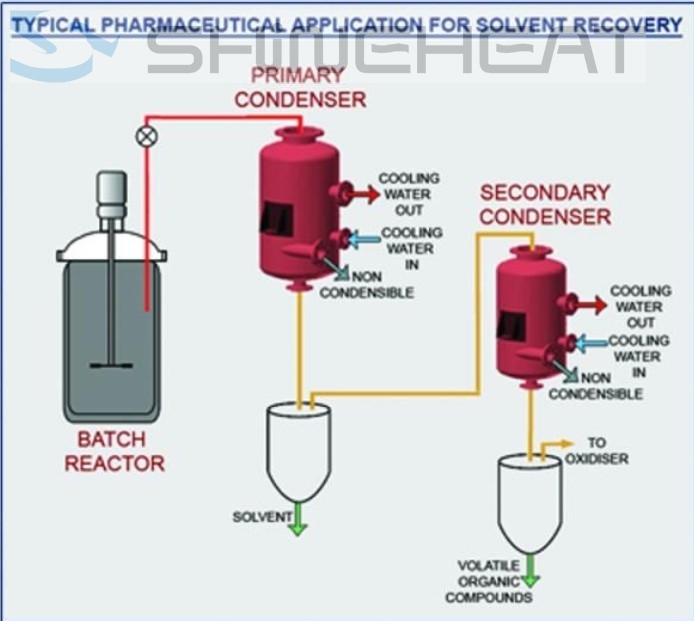

The spiral plate heat exchanger will carry out the important role for recovering expensive solvents from reactors.

It need compact and efficient design for Vacuum duties with Maximum solvent recovery.

It need Primary and Secondary Spiral Condensers in API and Bulk Drug Industries.

Spiral Heat Exchanger apply for Solvent Condenser in Bulk Drug Industries.

The Job Description

The spiral plate heat exchanger will carry out the important role for recovering expensive solvents from reactors.

It need compact and efficient design for Vacuum duties with Maximum solvent recovery.

It need Primary and Secondary Spiral Condensers in API and Bulk Drug Industries.

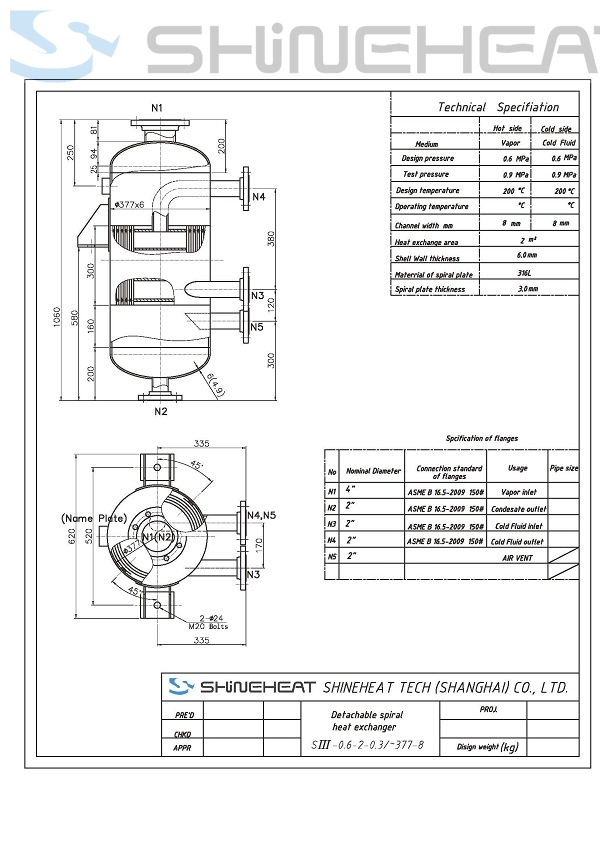

SHINEHEAT SPIRAL PLATE HEAT EXCHANGER SOLUTION

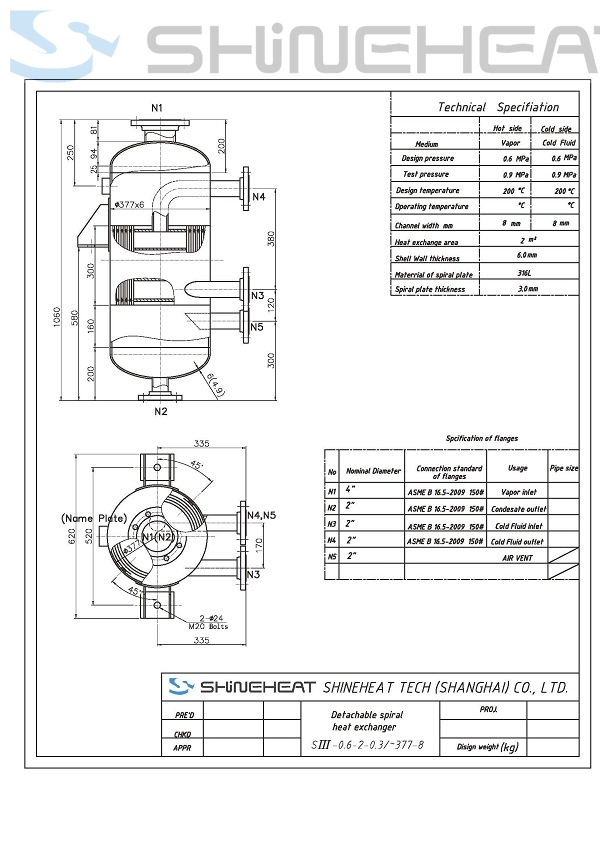

The Most Compact Design for “Direct-Pass” Spiral Plate Heat Exchanger,

The vapor circulates, cross flow, in an alternated channel, with negligible pressure drop and the coolant circulates in an accessible spiral channel.

The Lowest Maintenance Cost for operation. Primary and Secondary Solvent Condensers were vertically design, low cost in installation. Single Pass Spiral flow avoids clogging in operation, no extra service job needed.

The Highest Efficient in Solvent Recovery, Above 95% Solvent Recovery higher than other conventional Heat Exchanger.

The Most Durable Structure for All Welded Pressure Vessel Design, ideal application for Vacuum or Negative Pressure Condition.

SHINEHEAT SPIRAL PLATE HEAT EXCHANGER SOLUTION

The Most Compact Design for “Direct-Pass” Spiral Plate Heat Exchanger,

The vapor circulates, cross flow, in an alternated channel, with negligible pressure drop and the coolant circulates in an accessible spiral channel.

The Lowest Maintenance Cost for operation. Primary and Secondary Solvent Condensers were vertically design, low cost in installation. Single Pass Spiral flow avoids clogging in operation, no extra service job needed.

The Highest Efficient in Solvent Recovery, Above 95% Solvent Recovery higher than other conventional Heat Exchanger.

The Most Durable Structure for All Welded Pressure Vessel Design, ideal application for Vacuum or Negative Pressure Condition.

SHINEHEAT SPIRAL PLATE HEAT EXCHANGER SUPPLY SCOPE

Material: Carbon Steel, SS304, SS316, SMO254, C276, Duplex2205

Transfer Area: 2~500 m2