A Pillow plate consists of two plates,which are fully welded along the sides and ends. In the middle area the Pillow plates are covered with a pattern of spot welds, whose interrelated position decides the level of pressure and type of flow.

For certain applications, we add extra welding paths in order to control the actual flow through the plates. This will increase the velocity of the flow between the plates and change the heat transfer values

The pillow-shaped design creates excellent turbulence and provides a self-supporting construction. Our Pillow plates do not transfer any forces outwards onto the next plate, which would otherwise have to be absorbed by housing pressure plates

Welded Pillow Plate Corrugations

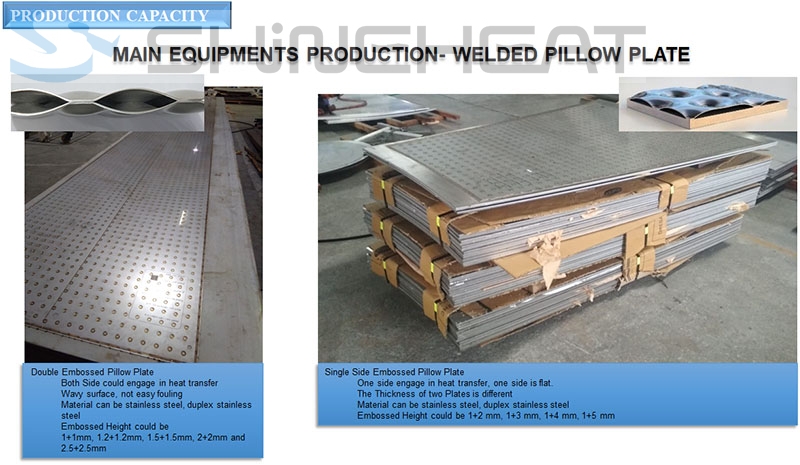

Double Embossed Pillow Plate

Both Side could engage in heat transfer

Wavy surface, not easy fouling

Material can be stainless steel, duplex stainless steel

Embossed Height could be 1+1mm, 1.2+1.2mm, 1.5+1.5mm, 2+2mm and 2.5+2.5mm

Single Side Embossed Pillow Plate

One side engage in heat transfer, one side is flat.

The Thickness of two Plates is different

Material can be stainless steel, duplex stainless steel

Embossed Height could be 1+2 mm, 1+3 mm, 1+4 mm, 1+5 mm

Usage for Welded Pillow Plates

Pillow Plate Vessel & Tank

Performed as to Cooling Jacket or Heating Jacket, Pillow Plate could be rolled into specific specificiations and forming into different Vessel and Tank for various Heating and Cooling applications.

The Typical Applications

• Beverage processing vessel

• Fermenters, beer vessel, cooking vessel

• Dairy processing vessel

• Pharmaceutical and processing vessel

• Storage tank

• Reactor vessel

The Main Parameters for Welded Pillow Plates

* Working pressure can go up to > 100 bar

* Jacket thickness varying from 0,8 to > 2,5 mm,

* Vessel thickness from 2,0 to > 20 mm.

* Standard: ASME, AD2000, EN13445 and PED.